One

of the factors that can have a great impact on corrosion severity is the

geometry of the service application. Obvious cases are those involving

crevices, seams, laps and welds where the formation of an occluded cell can

result in differences between local and bulk solutions. Other factors such as

hot wall effects can also complicate service conditions. In some cases, the

whole service condition may bring together somewhat unique combinations of

solution and geometric variables which can not be easily understood. One such

case that illustrates this situation is exhibited by corrosion under insulation

(CUI).

CUI

can result from a build-up of water and contaminants in the annular space

between the metal surface and the thermal insulation. It is compounded by

situations such as hot wall effects and alternate wetting and drying. The

problem typical of CUI is that corrosion rates are typically greater than predicted

based on aqueous corrosion data produced from either open or closed system

measurements. In an open system, corrosion rates are generally low due to the

decreasing solubility of oxygen with increasing temperature. The CUI situation

more closely represents a closed system; however, prior studies attempting to

simulate CUI by these methods have generally been unsuccessful.

Recently,

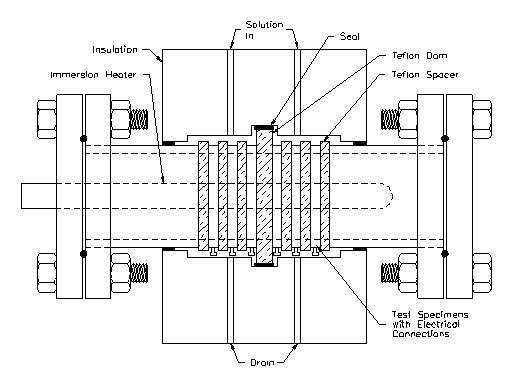

experiments were conducted with a special test cell designed at CLI

International, Inc. to model CUI (See Figure 1). This novel approach included the use of an internally heated metal tune and isolated ring specimens surrounded by insulation material. The annular space was filled with a simulated atmospheric condensate. Corrosion was assessed using ring specimens that could be monitored using linear polarization resistance (LPR) techniqies per ASTM G59, mass loss per ASTM G1 and localized corrosion rate per ASTM G46. Tests can incorporate isothermal conditions, thermal cycling and alternate wet dry conditions

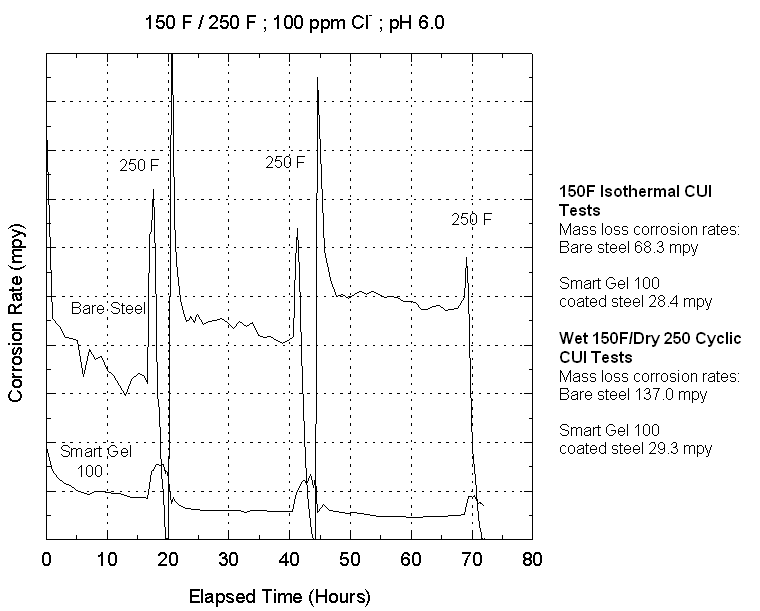

Figure

2 shows the comparison of isothermal and cyclic tests. The mass-loss corrosion

rates show values comparable to those associated with CUI in field and plant

operations. Of particular interest is the variation in corrosion rate with time

for the cyclic tests. The trend indicates that periods of maximum corrosivity

involve the periods during re-wetting of the metal surface following the dry

cycle. The peaks in corrosion rate are 2 to 3 times the steady state corrosion

rates. Furthermore, for cyclic wet-dry conditions, the steady state corrosion

rate also increases with time. The benefit of protective surface treatments

which results in much lower rates of corrosion versus time can also be seen.

Figure 1 - CUI Test Cell

Figure 2 - Instantaneous

and mass-loss corrosion rates for CUI system